Copper Smelting Industry

Let’s start with a basic premise: Copper does not come out of the Earth in pure form. It has to be liberated from impurities, and that liberation process is what we call smelting.

Copper smelting plays a foundational role in modern life — from electrical wiring, motors, electronics, plumbing, to renewable energy systems.

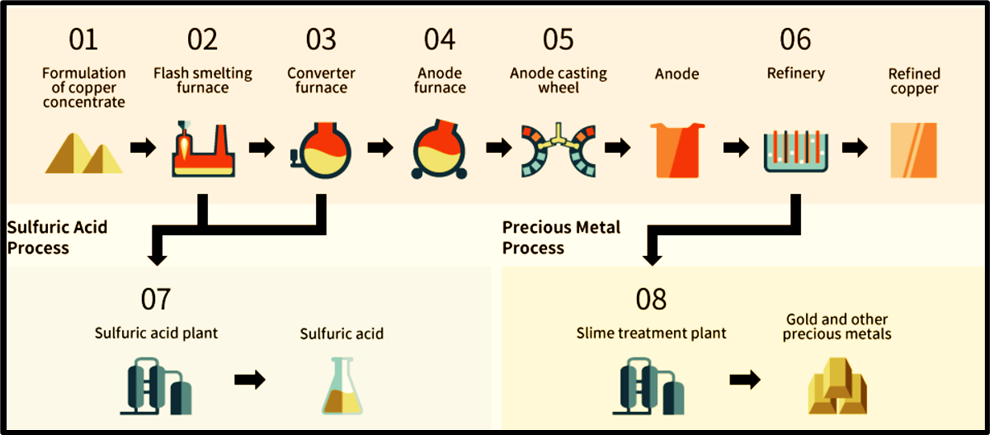

🔬 Smelting Process in the Copper Industry: Step-by-Step

This is essentially a multi-stage purification process. Let’s understand it:

1. Ore Preparation

- Raw copper ores have only 0.5–2% copper. So, first they are:

- Crushed

- Milled

- Concentrated (via froth flotation)

- This yields a 25% copper concentrate.

🧠 Think of it as turning a haystack into a small pile of hay needles.

2. Smelting

- The concentrate is heated at ~1200°C in furnaces.

- Flash smelting is common — oxygen is blasted in, oxidising sulphur and iron.

- Result: Molten copper (matte) and slag separate.

3. Converting

- The molten copper still has some sulphur and iron.

- It is transferred to a converter, where air/oxygen is injected again.

- Impurities oxidise into slag, leaving blister copper (98–99% purity).

4. Electro-Refining

- In this final stage:

- Impure copper = anode

- Pure copper = cathode

- Electricity is passed through an acid bath.

- Result: 99.99% pure copper deposits on the cathode.

💡 This step separates economic copper from technically pure copper, essential for electrical applications.

You can watch this YouTube video for better insights: Inside America’s Super Smelter

🌍 Global Distribution of Copper Smelting Industries

The global pattern of copper smelting follows resource availability, infrastructure, demand, and policy ecosystem.

🔶 Asia-Pacific: The Powerhouse

🇨🇳 China

- Dominates global smelting — due to:

- Huge domestic demand

- Vertical integration (from mining to electronics)

- Heavy investments in smelting technology

🇯🇵 Japan & 🇰🇷 South Korea

- Lack local ores but import heavily

- Run large, efficient import-based smelters (Ex: Pan Pacific Copper)

🇮🇩 Indonesia

- Emerged due to Grasberg Mine in Papua (rich in copper and gold)

- New policies now mandate in-country smelting before export

🔷 Latin America: Resource-Rich Backbone

🇨🇱 Chile – World’s Copper Capital

- 24% of global production

- Rich porphyry copper deposits in Andes Mountains

- Infrastructure (ports, railways), political stability, and pro-export policies made it a copper superpower.

🇵🇪 Peru

- Antamina & Las Bambas mines are leading contributors.

- Government policies support mining exports.

🟥 North America

🇺🇸 USA

- Smelting centred in Arizona (Morenci), Utah (Bingham Canyon), and Montana

- Focused more on value-added copper products like wiring and industrial components

🟩 Australia

- Important due to Olympic Dam (South Australia) and Mount Isa Mines (Queensland)

- Integrated mining and smelting systems in isolated yet rich mineral zones

🇷🇺 Russia

- Copper smelting facilities in Ural Mountains

- Strong metallurgical base inherited from the Soviet era

🇮🇳 Distribution of Copper Smelting Industries in India

Copper ore in India is modest in quantity but the smelting capacity is well developed due to imported concentrates and strong domestic demand.

Let’s understand this by region:

📍 Central India – Resource-Driven Smelting

- Madhya Pradesh (Malajkhand):

- India’s largest integrated mine-smelter complex

- Operated by Hindustan Copper Limited (HCL)

- Other centres: Balaghat and Chhindwara

📍 Gujarat – Import-Based Smelting Hub

- Dahej (Hindalco):

- Large smelter relying on imported copper concentrate

- Jhagadia Copper Ltd (Bharuch): A private sector smelter

🧠 Proximity to ports and infrastructure makes Gujarat ideal for import-led refining.

📍 Other Centres

- Tuticorin (Tamil Nadu) – Sterlite Copper (now shut due to environmental issues)

- Khetri (Rajasthan) – A historic mining-smelting complex

- Indian Copper Complex (Jharkhand) – Older but significant facility

🔍 Locational Factors Influencing the Copper Smelting Industry

The copper smelting industry is capital- and resource-intensive. Thus, its location is influenced by a mix of natural endowments, infrastructure, labour, and policy ecosystem.

Let’s examine the key locational factors:

1. Proximity to Copper Resources

- Transporting ore over long distances is costly, especially since copper ores contain only 0.5–2% metal.

- Hence, smelters are often located near mines.

- Example: El Teniente in Chile, the world’s largest underground copper mine, supports smelting operations nearby.

2. Availability of Energy

- Smelting is highly energy-intensive. Thus, low-cost, reliable electricity is a prime locational factor.

- Example: Guixi Smelter in China is strategically located near coal reserves to ensure energy security.

3. Water Resources

- Water is vital for ore processing, cooling, and gas scrubbing.

- Challenge Example: Khetri (Rajasthan) faces water scarcity, which has necessitated recycling and conservation practices.

4. Infrastructure & Transportation

- Efficient rail, road, and port networks are essential for:

- Importing concentrates (in India’s case)

- Exporting refined copper

- Examples:

- Tuticorin Smelter (India): Gains from port proximity.

- Chuquicamata Smelter (Chile): Near Antofagasta Port, a global copper export hub.

5. Skilled Labour

- Smelting operations require a technically proficient workforce in metallurgy, engineering, and operations.

- Example: Aurubis Hamburg Smelter (Germany) thrives due to Germany’s industrial and educational strength.

🔄 Forward Linkage: Acid Industry

A classic case of industrial symbiosis:

- During copper smelting, Sulphur Dioxide (SO₂) is released.

- Instead of wasting it, it’s used to produce Sulphuric Acid — a crucial input for:

- Fertilisers (e.g., Phosphoric Acid)

- Detergents, dyes, explosives

- Example: Sterlite Copper, Tuticorin – had integrated sulphuric acid & phosphoric acid plants based on SO₂ recovery.

💡 Forward Linkage means: Product of one industry becoming input for another — this increases resource efficiency and profitability.

🇮🇳 Significance of the Copper Smelting Industry in India

Let’s look beyond just metal:

🔧 Economic Backbone

- Supports construction, telecom, transportation, and renewables

- Generates direct and indirect employment

- Forms a critical part of infrastructure-led growth

🌉 Infrastructure Catalyst

- Copper is integral to:

- Power transmission lines

- EVs & green energy

- Urban infrastructure

🧠 Copper acts as a metallic multiplier — enabling multiple sectors through one industrial chain.

⚖️ Sterlite Copper Plant Case: Industrial vs Environmental Conflict

This case represents the classic dilemma of industrial growth vs environmental sustainability.

🏭 Background

- Located in Tuticorin (TN), in a dense industrial cluster.

- Produced over 50% of India’s refined copper.

- Also had acid production units, making it an integrated facility.

🌊 Environmental Concerns

- Located near the Gulf of Mannar, a sensitive marine ecosystem.

- Faced allegations of:

- Overuse of groundwater & river water (Thamirabarani)

- Emission of SO₂, heavy metals, particulate matter

🪧 Social Protests and Closure

- Persistent complaints + regulatory lapses = massive protests in 2018

- Police firing killed 13 protestors.

- TN Government ordered closure, and SC upheld the decision recently.

📉 Impact: Major drop in India’s refined copper output ➡️ increased imports ➡️ trade imbalance in copper sector.

🌎 Copper Smelting Industry — Global Snapshot

| Aspect | Leading Countries |

|---|---|

| Top Producer | Chile, Peru, China, DRC, Mexico |

| Top Consumer | China, India, US, Japan, Germany |

| Top Exporter | Chile, Peru, DRC, Australia, Mexico |

| Top Importer | China, US, Germany, Japan, South Korea |

⚠️ Challenges Faced by India’s Copper Smelting Industry

| Challenge | Explanation |

|---|---|

| ⚙️ Low Ore Availability | India produces only 8% of required ore; rest is imported. |

| 🏭 Outdated Mining Methods | Low yields and high costs due to poor extraction tech. |

| 💡 Energy & Infrastructure | High power costs and logistic bottlenecks hamper competitiveness. |

| 🌱 Environmental Regulations | Necessary but restrict expansion; public resistance high. |

🚀 Future Prospects of India’s Copper Smelting Sector

📈 Growing Domestic Demand

- Expected to double by 2030 due to:

- Renewable energy (solar panels, wind turbines)

- Electrification (EVs, power lines)

- Urbanisation and Smart Cities

🛠️ Policy & Technology

- PMKKVY promotes domestic exploration.

- Tech upgrades (like Ausmelt, ISASmelt) can:

- Improve efficiency

- Cut emissions

- Lower energy use

🌐 Strategic Location Advantage

- Proximity to copper-consuming nations (China, ASEAN)

- Coastal locations (Dahej, Tuticorin) = potential for export-oriented smelting