Silk Industry

🧵Understanding India’s Silk Industry: An Overview

Let us first develop a bird’s-eye view.

India is the second-largest producer of silk in the world, after China. However, it’s the only country producing all five kinds of silk – Mulberry, Eri, Muga, Tassar, and Oak Tassar. Among these, Mulberry silk contributes the most to India’s silk production.

Read about Sericulture from the Agriculture à Allied Agriculture section first before proceeding

State-wise Contribution in Silk Production

Now, let’s systematically go through the top silk-producing states, and understand which regions in these states are prominent silk belts.

🥇 1. Karnataka – 32% of India’s Silk Production

- Major Regions: Old Mysore Region — includes Mysuru, Kolar, Bengaluru Rural, Chikkaballapura.

- Karnataka is often called the Silk State of India.

- Favourable climatic conditions, especially for Mulberry silk, and support from Central Silk Board make Karnataka a leader.

🥈 2. Andhra Pradesh – 25%

- Major Regions: Anantapur and Chittoor, part of Rayalaseema.

- Rayalaseema is known for its hot and dry conditions, which suit Tassar and Mulberry silk cultivation.

🥉 3. Assam – 16%

- Region: Brahmaputra Valley

- Assam is the only state producing the rare and heritage Muga silk — golden-yellow in color and unique to the region.

4. Tamil Nadu – 7%

- Regions: Coimbatore, Dharmapuri, Salem

- Tamil Nadu is famous not just for production but also for exquisite silk weaving centers like Kanchipuram.

5. West Bengal – 4.5%

- Regions: Murshidabad, Birbhum

- Known for traditional silk sarees and ancient weaving culture.

6. Jharkhand – 3%

- Region: Singhbhum

- Important for Tassar silk, often collected from wild forests, and vital for tribal livelihoods.

Major Silk Industry Centres in India

Apart from production, weaving and craftsmanship form the soul of India’s silk identity. Let’s look at important centres known for weaving, dyeing, and crafting silk products:

- Mysore (Karnataka) – Known for rich Mulberry silk and Mysore silk sarees.

- Varanasi (Uttar Pradesh) – Globally renowned for Banarasi sarees, with intricate zari work.

- Dharmavaram, Pochampalli, Venkatagiri, Narainpet (Andhra Pradesh) – Known for Pochampalli ikat and silk sarees.

- Kanchipuram (Tamil Nadu) – Called the Silk City, famous for temple borders and gold zari sarees.

- Murshidabad (West Bengal) – Has deep historical roots in silk production.

- Bhagalpur (Bihar) – Called the Silk City of Bihar, famous for Tussar silk sarees.

- Kashmir (J&K) – Known for fine, handwoven silks.

Indian Silk in the Global Market

India not only caters to its huge domestic demand but also exports silk products such as:

- Raw silk, silk yarn

- Fabrics, garments

- Silk waste

- Handloom items

🌍 Top Export Destinations: USA, UAE, China, UK, Australia

Employment Generation

- The silk industry is highly labour-intensive, especially in weaving and reeling.

- In 2021–22, it generated employment for 8.8 million people, mostly in rural areas — a key livelihood sector for women and marginal farmers.

Silk Weaving Clusters in India (State-wise)

Let’s go state by state and note the notable weaving clusters where traditional handlooms and artisanal skill thrive:

| State | Major Silk Weaving Clusters |

|---|---|

| Andhra Pradesh | Dharmavaram, Venkatagiri, Koyyalagudem |

| Assam | Sualkuchi (popularly called the Manchester of Assam) |

| Bihar | Bhagalpur, Kishanganj, Gaya, Darbhanga, Nalanda, Madhubani, Siwan, Patna |

| Chhattisgarh | Champa, Chanderi, Raigarh, Bilaspur, Sirsiwa |

| Gujarat | Surat, Cambay |

| Jammu & Kashmir | Srinagar |

| Karnataka | Bangalore, Anekal, Ilkal, Molakalmuru, Melkote, Kollegal |

| Maharashtra | Paithan, Yeola |

| Tamil Nadu | Kanchipuram, Arni, Salem, Kumbhakonam, Tanjavur |

| Telangana | Pochampalli, Narainpet |

| Uttar Pradesh | Varanasi, Feeder Towns |

| West Bengal | Bishnupur, Murshidabad, Birbhum |

📍Factors Responsible for Location of Industry in India

🥇 Karnataka – The Powerhouse of Indian Silk

Karnataka accounts for over 32% of India’s total silk production and produces more than half of India’s mulberry silk. Let’s decode why this state, particularly the Old Mysore region, became the nucleus of the silk industry.

1. Historical Legacy

- In the 18th century, Tipu Sultan imported silk cocoons from China and even sent artisans to Bengal to learn sericulture techniques.

- During World War II, Mysore silk was used in parachute manufacturing, giving the industry a strategic boost.

2. Raw Material Availability

- Karnataka is the largest producer of raw silk in India.

- Specialises in Mulberry silk, which is more refined and widely demanded in the saree and textile industries.

🔍 Note: Silk is not a weight-losing industry—meaning raw material transportation isn’t very expensive—yet having local availability provides cost and logistical advantages.

3. Skilled & Cheap Labour

- The region has a rich sericultural tradition, with rural and semi-urban populations engaged in silkworm rearing and weaving.

4. Technology & Research

- The Central Sericultural Research & Training Institute (CSRTI) in Mysore drives innovation, including high-yield mulberry and silkworm breeds.

- Since 1991, Japan International Cooperation Agency (JICA) has supported India’s transition to bivoltine silk, a high-grade silk from silkworms that lay two batches of eggs per year. Karnataka is a front-runner in this.

5. Water Availability

- Cauvery and Arkavathi Rivers offer abundant water required for washing, bleaching, dyeing—critical parts of silk processing.

6. Established Market Linkages

- Karnataka not only exports silk directly but also supplies to key weaving hubs like Varanasi, Kanchipuram, Bhagalpur, and even Kashmir.

7. Government Support

- The iconic Mysore Silk is produced by the Karnataka Silk Industries Corporation and enjoys Geographical Indication (GI) tag protection—ensuring quality and branding support.

🥈 Varanasi – The Cultural Capital of Silk Weaving

Unlike Karnataka, Varanasi is not a silk-producing region, but it is a legendary weaving hub known globally for its Banarasi sarees.

1. Historical Patronage

- The Mughals greatly patronised the weaving of rich silk brocades and sarees in Varanasi.

- This craftsmanship legacy has continued unbroken for centuries.

2. Skilled Labour Force

- The Ansari Muslim weavers, known for their intricate weaving skills, have been carrying this tradition since the Mughal era.

- The region thrives on handloom and powerloom weaving—over 85% of the silk consumed is handwoven.

3. Raw Material Supply

- Silk yarn is sourced from Karnataka, while high-quality silk is sometimes imported from China.

- Zari threads, which are metallic threads made of gold or silver, are brought from Gujarat.

4. Water Resource

- Situated on the banks of the Ganga, Varanasi has access to abundant water for dyeing and washing.

5. Robust Market

- Banarasi sarees enjoy pan-India demand, especially in wedding and festive wear.

- These are sold across India and also exported internationally.

6. Government Recognition

- In 2009, Banarasi sarees and brocades were granted GI Tag status.

- This GI status covers six districts of eastern Uttar Pradesh — Varanasi, Mirzapur, Chandauli, Bhadohi, Jaunpur, and Azamgarh — allowing only products from these districts to legally carry the Banaras label.

🥉 Kanchipuram – The “Silk City” of South India

Located in Tamil Nadu, Kanchipuram is famed for its handwoven Kanchipuram sarees, often seen in weddings and traditional functions across South India. But what made this place evolve into a silk hub? Let’s decode it:

1. Historical Roots

- During the rule of Krishnadevaraya of the Vijayanagara Empire, two prominent weaving communities from Andhra Pradesh—Devangas and Saligars—migrated to Kanchipuram and settled here.

- These communities were already skilled in handloom weaving, and Kanchipuram became their new cultural and economic base.

2. Skilled Labour Force

- Kanchipuram boasts a hereditary weaving tradition, where skills are passed down generations.

- The artisans are known for weaving sarees with contrasting borders, temple motifs, and heavy zari work.

3. Raw Materials

- Silk yarn comes from Karnataka, the nearby silk-producing state.

- Cotton yarn is also locally available—useful in blending or in making lighter versions.

- Zari threads—made from fine gold or silver—are brought from Gujarat.

4. Water Source

- The town lies near the left bank of the Palar River, which provides necessary water for dyeing and finishing.

5. Market Demand

- Kanchipuram sarees are a staple for South Indian weddings, festivals, and temple ceremonies.

- The cultural and emotional connect makes them a premium product.

6. Government Recognition

- Kanchipuram silk sarees enjoy a Geographical Indication (GI) tag, ensuring protection for its identity and traditional craftsmanship.

❄️ Jammu & Kashmir – The Cold-Climate Silk Region

J&K might surprise you as a silk-producing region, but its unique climate and heritage make it a distinguished player—especially in producing high-quality bivoltine mulberry silk.

1. Historical Significance

- The region was once a vibrant stop along the ancient Silk Route, linking Central Asia with India and China.

- The modern silk industry was established in Srinagar in the 1890s under British rule, seeking to diversify the economy.

2. Labour & Cultural Transition

- With the decline of Kashmir’s shawl industry, many artisans were retrained or absorbed into silk production to sustain employment.

- Sericulture and weaving thus became important sources of rural livelihood.

3. Raw Material Excellence

- J&K produces some of India’s best quality bivoltine silk—this is due to its cool climate, ideal for healthy silkworm growth.

- Bivoltine silk is finer, shinier, and has better tensile strength compared to multivoltine silk.

4. Technology Adoption

- Even during colonial times, Europe-imported reeling machinery was introduced in Srinagar to boost silk yarn quality.

5. Market Linkages

- While it’s not a major weaving centre like Varanasi or Kanchipuram, Kashmiri silk sarees enjoy good domestic demand due to their fine quality.

🚧 Issues Faced by the Indian Silk Industry

Despite India’s position as the second-largest silk producer globally, several challenges hinder its full potential. Let’s understand this:

1. Dependence on Imports (Especially from China)

- India imports a large quantity of high-quality bivoltine silk from China.

- Why? Because Chinese silk is uniform in thickness, making it smoother and more compatible with power looms.

- This import-dependence creates a vulnerability in pricing and supply.

2. Inconsistent Raw Silk Quality

- Indian silkworm cocoons often result in uneven thickness.

- This inconsistency is due to:

- Poor silkworm breeds in some regions.

- Outdated reeling machines, which compromise yarn uniformity and strength.

3. Rise of Synthetic Fibres

- Nylon and artificial silk (viscose rayon) are:

- Cheaper.

- Low-maintenance.

- Visually similar to real silk.

- This has affected the popularity and affordability of genuine silk products.

4. Informality & Low Investment

- A large chunk of India’s silk industry operates in the informal sector—small households or village-based units.

- These units face:

- Low access to capital.

- Lack of modern machinery.

- No economies of scale.

- Result: They struggle to compete with large-scale producers and exporters.

🧵 Final Thoughts

India’s silk story is not just about threads and textiles—it’s a tapestry of migration, tradition, rivers, rulers, research, and resilience.

Whether it’s:

- Tipu Sultan’s Mysore silk,

- Mughal-inspired Banarasi brocades,

- Temple-woven Kanchipuram sarees, or

- Bivoltine cocoons from snowy Kashmir,

each silk centre has evolved due to a unique interplay of historical, physical, and socio-economic factors.

🇨🇳 China – The Global Silk Superpower

China has long been synonymous with silk. It is not just the world’s largest producer, but also a leading exporter and consumer of silk. Let’s explore how this dominance came to be:

1. Historical Legacy

- Silk was discovered in China around 3500 BCE. The secret of its production was protected for centuries, giving China a monopoly in the ancient world.

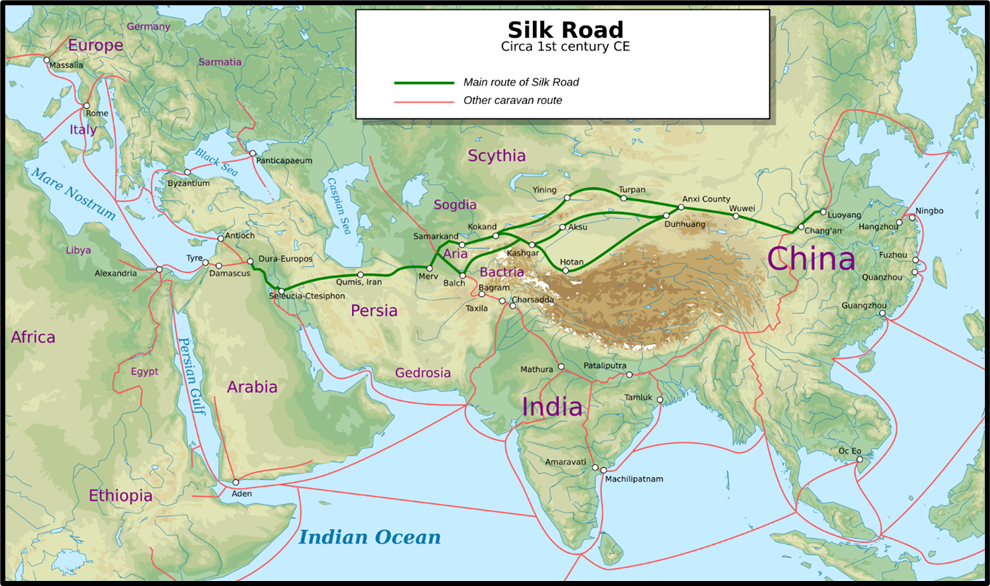

- The ancient Silk Route was named after this very fabric! (see fig.)

2. Labour Force

- China has access to low-cost labour, which is essential in labour-intensive sericulture.

- It also has a skilled weaving community, with generational knowledge in rearing silkworms and weaving fine silk.

3. Raw Material Availability

- High-quality silk is produced, particularly south of the Yangtze River delta—a region with favourable temperature, rainfall, and soil conditions.

- Chinese silk is well-suited for power looms, ensuring mass production of uniform quality.

4. Favourable Climate

- China supports all three types of silkworms:

- Univoltine – hatch once a year (best quality),

- Bivoltine – hatch twice a year,

- Polyvoltine – hatch multiple times.

- This climatic suitability allows for year-round sericulture.

5. Technological Innovation

- Chinese scientists have developed hybrid silkworms by cross-breeding European and Japanese varieties.

- In some areas, silkworms are reared up to seven times a year, maximising productivity.

6. Innovative Practices

- In the Pearl River Valley, farmers integrate sericulture with fishery—feeding dead silkworms and waste to fish, creating a sustainable and profitable model.

7. Water Supply

- The Yangtze River supports the industry with water for washing, bleaching, and dyeing.

8. Market & Export

- Major buyers of Chinese silk include India, Europe, and the USA.

- China is the top silk exporter in the world.

9. Government Support

- The Chinese government promotes silk cooperatives and communes, and gives financial incentives for modernising equipment and R&D.

🌏 Silk Industry Outside India and China – A Declining Dream

Silk production has been unsuccessful or unsustainable in many countries. Let’s examine key examples:

🇯🇵 Japan – Rise and Fall of the Silk Empire

➤ Rise:

- In medieval times, silk production was a secondary income for Japan’s poor peasants.

- After the Meiji Restoration (1868), the port of Yokohama became a hub for silk export.

- By early 20th century, Japan produced 60% of the world’s raw silk, supplying Britain and the U.S..

➤ Fall:

- Post-World War II, synthetic fibres like nylon replaced silk.

- Labour costs increased, and industries shifted to automobiles (e.g., Toyota) and electronics.

- Westernisation of Japanese culture also reduced domestic demand.

- By 1975, Japan stopped being a net exporter of silk.

🇺🇸 United States – A Failed Attempt

- Sericulture was briefly tried in Virginia and Georgia between the 1600s–1760s.

- A mulberry tree blight in 1840s forced reliance on Chinese silk imports.

- The silk industry could not survive due to:

- More profitable crops like tobacco, soybean, and cotton.

- Unsuitable climate for high-quality silkworm rearing.

- Hence, the U.S. eventually gave up on silk production.

🇪🇺 Europe – Short-Lived Aspirations

➤ Attempts:

- Sericulture was introduced in France and Italy in the 19th century.

- However, epidemics among silkworms in the 1840s led to industry collapse.

➤ Challenges:

- High labour costs made revival unviable.

- Instead, European industries like:

- Cotton textiles in Lombardy and Prato (Italy),

- Silk fashion in Lyon (France),

flourished using imported raw materials, especially from China.

➤ Modern Revival (Fashion-Driven):

- Today, France and Italy are leaders in luxury fashion.

- They import silk from China and convert it into high-end designer products.

- Interestingly, to support this, direct flights between China and Italy operate to ferry Chinese workforce.

📊 Global Silk Trade Snapshot

| Category | Leading Country(s) |

|---|---|

| Top Silk Producers | China, India, Uzbekistan |

| Top Silk Importers (Value) | India, Romania, Vietnam |

| Top Silk Exporters (Value) | China, Vietnam, Italy |

🧶 Final Reflection

The story of silk is one of geography, history, culture, economy, and technology woven together. While India and China dominate the production and consumption, the silk industry’s cultural essence still shines across the globe—from the bridal sarees of Kanchipuram and Varanasi to the haute couture ramps of Milan and Paris.

If you’re preparing for Geography, this topic interlinks industrial location theories, economic geography, agro-based industries, and global trade—making it a high-yield area for UPSC.