Petrochemical Industry

Introduction: What is the Petrochemical Industry?

As we have already studied comprehensively, crude oil, or petroleum, is a naturally occurring mixture of hydrocarbons found beneath the Earth’s surface. But crude oil in its raw form is not very useful. So, what do we do?

We refine it — that is, we process it through a series of steps to extract valuable products like:

- Fuels (e.g., petrol, diesel, kerosene),

- Petrochemicals (used to manufacture plastics, fertilizers, synthetic fibres, etc.),

- Lubricants (used in machinery, vehicles, etc.)

Thus, petrochemical industries play a crucial role — not just in the energy sector, but across industries like transportation, agriculture, textiles, pharmaceuticals, etc.

Refining Process: How Crude Oil Becomes Useful

Imagine the refining process as a multi-step cooking recipe — each step designed to extract a specific ‘dish’ from a complex mixture. Let’s go step-by-step:

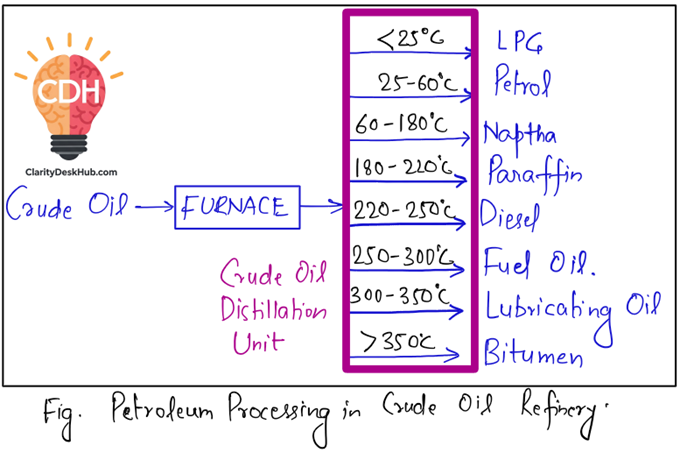

a) Distillation – The First Cut

Crude oil is heated in a large tower (fractionating column). Different components boil at different temperatures, so they separate out:

- Lower boiling points (top): petrol, LPG, naphtha

- Higher boiling points (bottom): diesel, lubricants, heavy oils

This is purely a physical process, based on boiling points.

b) Conversion – Breaking the Big into Small

Now comes the chemical part. Heavier fractions (like residual oil) are converted into lighter products using:

- Catalytic Cracking

- Hydrocracking

Think of it like breaking a large rock into small usable pebbles.

c) Treatment – Purifying the Product

This stage removes impurities like sulfur, using:

- Desulfurisation

- Hydrotreating

The goal is to make fuels cleaner and comply with environmental norms.

d) Blending – Tailoring the Output

Finally, products are blended for specific performance — like adding ethanol to petrol or adjusting octane levels.

In exams you can draw this simple diagram to illustrate distillation part of Crude oil processing:

Global Distribution of Petrochemical Industry: Who Produces and Why?

Let’s now look at the global pattern — where these industries are located and why they are there.

🌍 Middle East – A Natural Leader

The Middle East has:

- Abundant oil and gas reserves

- Strategic ports and investment hubs

Hence, major hubs have emerged in:

- Saudi Arabia (Jubail, Yanbu)

- Qatar (Ras Laffan)

- UAE (Ruwais)

But there’s an interesting shift:

Earlier, industries were built close to oil wells. But that is no longer always preferred. Why?

👉 Changing Location Factors

| Factor | Explanation |

|---|---|

| Refineries Near Source are Risky | Oil wells may dry up, causing huge financial loss. So, locating only near raw material is not always safe. |

| Not a Weight-Losing Industry | Unlike iron ore or sugarcane, crude oil loses only ~10% weight during refining. So, transport cost saving is minimal. |

| Better to be near Market | Since most refined products are consumed in industrial areas, it’s often better to be closer to the market than the source. |

| Policy Influence | E.g., after the 1970s, nationalisation in Middle East discouraged private players from setting up nearby refineries. |

🔍 Examples of Refineries Near Oil Fields

- Global: Ras Tanura Refinery, Saudi Arabia (near eastern oil fields)

- India: Digboi Refinery, Assam (near Digboi oil fields – Asia’s oldest refinery)

Regional Profiles of Petrochemical Industries

Now, let’s take a continent-wise overview, focusing on key centres and reasons:

🛢️ North America

- USA: Especially Gulf Coast (Texas, Louisiana) — rich in shale gas, proximity to ports.

- Also present in Midwest and Northeast.

- Canada: Alberta (oil sands), Ontario, and Quebec are significant petrochemical zones.

🌏 Asia-Pacific

- A rapidly growing hub due to urbanisation, industrial growth, and rising population.

- China: Major centres in Shanghai, Tianjin, and Pearl River Delta.

- South Korea and Japan: Coastal refineries with advanced technology and export focus.

🌍 Europe

- Long-established, integrated industrial zones.

- Major clusters in:

- Germany (Rhine-Ruhr)

- UK, Netherlands, Belgium

These regions benefit from strong infrastructure, R&D, and demand from nearby industries.

🌎 South America

- Brazil, Mexico, and Venezuela are the top players.

- Locations are usually aligned with oil reserves and domestic demand.

🧠 So what we have read till now, let’s recap:

- Petrochemical industry = refining crude oil + producing usable products

- 4 Refining Steps: Distillation → Conversion → Treatment → Blending

- Location Factors Changed: Not always near oil wells now, due to market demand, risk of depletion, and policy changes.

- Global Leaders: Middle East (resource-based), USA (tech + shale gas), China (demand-driven), Europe (industrial clusters)

Distribution of the Petrochemical Industry in India

🛢️ Historical Background:

- India’s first oil refinery: Established in 1901, Digboi, Assam. This is why Digboi is called the birthplace of India’s oil industry.

- Second refinery: Tarapur, near Mumbai (1954).

🌍 India as a Global Refining Hub

- India ranks 4th globally in total refining capacity (after USA, China, and Russia).

- Total capacity: Approx. 249 MMTPA (Million Metric Tonnes Per Annum).

- India’s refining capacity exceeds domestic demand – so we export refined petroleum products.

- Public Sector Units (PSUs) dominate but private sector (esp. Reliance) plays a major role.

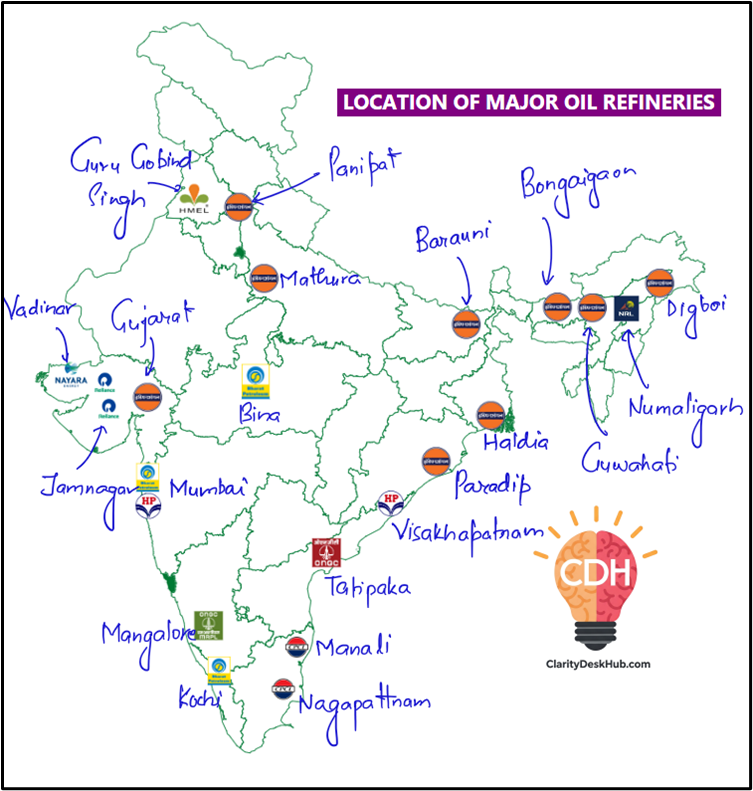

India’s petrochemical industry is strategically spread across four regions — West Coast, East Coast, Northern Region, and the North-East — based on access to raw materials, markets, ports, and infrastructure.

1. West Coast – The Petrochemical Powerhouse

This region is India’s most dominant zone, due to its geographical advantages and industrial ecosystem.

🔹 Mumbai Refinery

- One of India’s earliest refineries.

- Benefits from port connectivity, pipeline infrastructure, and proximity to a large market.

🔹 Gujarat – Petrochemical Capital of India

Why is Gujarat called this? Because it houses mega-refining and petrochemical complexes:

- Jamnagar – World’s largest refining complex (Reliance Industries)

- Hazira – Focused on petrochemicals (like polymers)

- Dahej – Integrated Petroleum, Chemicals and Petrochemicals Investment Region (PCPIR)

Let’s analyse Jamnagar Refinery as the best model for a refinery near a port.

📌 Why is Jamnagar Ideal?

| Factor | Explanation |

|---|---|

| Proximity to Ports | Close to Sikka and Navlakhi, enabling easy import of crude and export of refined products. |

| Deep-Water Access | Located near Gulf of Kutch, where large tankers (VLCCs) can dock — crucial for international oil transport. |

| Infrastructure | Presence of pipelines, storage terminals, logistics networks, and industrial support facilities. |

| Water Access | Sea water (for cooling and processing) is readily available from the Gulf of Kutch. |

🛢️ Other Port-based Refineries

- India: Chennai, Mangalore, Visakhapatnam

- Global: Rotterdam (Netherlands), U.S. East Coast

2. East Coast – Emerging Industrial Belt

The East Coast is rising due to:

- Raw material availability

- Proximity to Bay of Bengal ports

- Growing regional demand

🔹 Key Centres:

| Centre | Specialisation |

|---|---|

| Visakhapatnam (AP) | Evolving petrochemical hub — focuses on polymer and chemical production. |

| Paradip (Odisha) | Houses IOCL’s integrated refinery-petrochemical complex, producing fertilisers, polymers, and chemicals. |

| Haldia (WB) | Known for PVC and other plastic-based products — a major centre for Haldia Petrochemicals. |

3. Northern Region – Refining Near the Market

Here, the logic is reversed. Instead of being near raw materials or coastlines, the refineries are located near densely populated markets like Delhi, NCR, and North India.

🔹Greater Noida (UP): Focus on polymers and resins

🔹Panipat (Haryana): A major refinery + petrochemical complex

🔹Barauni (Bihar): Serves eastern and northern India

✨ Case Study: Mathura Refinery – A Market-Oriented Model

Let’s see why Mathura is a good example of a refinery located near the market.

| Factor | Explanation |

|---|---|

| Near the Market | Serves Delhi-NCR, Western UP, Rajasthan, etc. |

| Transport Network | Lies on the Golden Quadrilateral, ensuring quick distribution. |

| Labour Pool | Close to Delhi and Agra, ensuring skilled manpower availability. |

| Water Source | Uses Yamuna River for cooling and industrial needs. |

| Infrastructure | Strong storage and distribution network supports its operations. |

4. North-East – India’s Hydrocarbon Legacy Region

Despite being a remote and politically sensitive region, North-East India has a rich petroleum history and refinery presence.

🔹 Guwahati Refinery (IOCL)

- Among India’s oldest and most significant.

- Produces: petrol, diesel, jet fuel, LPG.

🔹 Digboi Refinery (Assam)

- Commissioned in 1901, this is India’s oldest refinery.

- Called “Gangotri of Indian Hydrocarbon Sector” — the origin point of oil industry in India.

🔹 Numaligarh Refinery (NRL)

- Located in Golaghat district, a joint venture between IOCL and Assam Govt.

- Serves the entire North-Eastern region, ensuring fuel security in a sensitive frontier area.

📌 Major Oil Refineries (Selected by Capacity & Geography)

| Location | Company | Capacity (MMTPA) |

|---|---|---|

| Jamnagar (SEZ & DTA) | Reliance (Private Sector) | 35 + 33 = 68 |

| Vadinar, Gujarat | Essar Oil (Private) | 20 |

| Kochi, Kerala | BPCL (PSU) | 15 |

| Panipat, Haryana | IOCL (PSU) | 15 |

| Paradip, Odisha | IOCL (PSU) | 15 |

| Mangalore, Karnataka | MRPL (PSU) | 15 |

| Koyali (Baroda), Gujarat | IOCL (PSU) | 13 |

| Mumbai (BPCL + HPCL) | BPCL + HPCL (PSUs) | 12 + 7.5 = 19.5 |

| Manali, Tamil Nadu | CPCL (PSU) | 10 |

| Bina, Madhya Pradesh | JV Refineries | 7.8 |

| Numaligarh, Assam | Numaligarh Refinery Ltd. | 3 |

| Smallest: Digboi, Assam | IOCL | 0.65 |

🔍 Remember: Jamnagar (Reliance) is the largest refinery complex in the world!

🧠 Summary Table (Quick Revision)

| Region | Key Centres | Special Features |

|---|---|---|

| West Coast | Jamnagar, Mumbai, Dahej | Port-based, world-class complexes |

| East Coast | Paradip, Vizag, Haldia | Market + raw material synergy |

| North India | Mathura, Panipat, Barauni | Close to demand centres |

| North-East | Guwahati, Digboi, Numaligarh | Historical + strategic importance |

📝 Final Takeaway

- Petrochemical industry location depends on raw material access, port facilities, market demand, and infrastructure.

- India’s strategy balances port-based refining with market-oriented hubs, ensuring national fuel and industrial security.

- Historical legacies (like Digboi) and modern giants (like Jamnagar) show how India’s petrochemical landscape is both diverse and strategically planned.

Locational Factors Influencing the Petrochemical Industry

Let’s start with a fundamental question:

Why are petrochemical plants located where they are?

There’s no one-size-fits-all. The location depends on multiple interacting factors — let’s decode them step by step.

1. Raw Material Proximity

Imagine setting up a sugar mill far from sugarcane fields — illogical, right? Similarly:

- Crude oil and natural gas are the lifelines of petrochemical industries.

- Proximity to reserves = lower transport costs + stable supply chain.

📍Examples:

- Middle East – massive oil fields, making it a global petrochemical hub.

- India – refineries in Mumbai and Dahej benefit from being close to offshore oil & gas fields in the Arabian Sea.

2. Infrastructure

It’s not just about resources, but also about moving them efficiently.

- Industries need pipelines, storage tanks, power supply, and transport connectivity.

- Refineries are high-investment assets, so even a minor disruption can lead to huge losses.

📍Example:

- The Gulf Coast of USA is a model of well-planned infrastructure with pipelines, ports, and storage terminals.

3. Market Proximity

What’s the point of producing if you can’t sell efficiently?

- Being close to consumer markets reduces logistics cost and ensures faster response to demand fluctuations.

- Especially important for time-sensitive products like fuels and packaged chemicals.

📍Example:

- Greater Noida, near Delhi-NCR, ensures rapid access to a massive market.

4. Port Access

Petrochemical industries are globally integrated — crude comes from one country, refining in another, sale in a third.

- Ports facilitate crude oil import and finished product export.

- Coastal locations reduce inland transportation and broaden international reach.

📍Example:

- Haldia Refinery benefits from access to Haldia Port on the East Coast.

5. Government Policies

The state plays a major role in shaping industrial geography.

- Policies like tax incentives, ease of doing business, or environmental clearances can attract or repel investment.

📍Example:

- India’s PCPIR (Petroleum, Chemicals & Petrochemicals Investment Region) program aims to develop large-scale petrochemical hubs with integrated infrastructure.

6. Environmental Considerations

This is the era of sustainability.

- Industries must align with pollution control norms, carbon emission regulations, and land-use planning.

- Location decisions increasingly favour cleaner technology adoption and environmental safeguards.

Saudi-UAE Mega Project in India

One of the biggest global collaborations:

- Saudi Aramco + Abu Dhabi National Oil Company (ADNOC) + Indian giants IOCL, BPCL, HPCL.

- Project site: Raigad district, Maharashtra

- Ownership: 50% foreign consortium, 50% Indian public-sector companies.

- Strategic aim: Tap into India’s rising fuel demand while strengthening diplomatic energy ties.

Significance of the Petrochemical Industry in India

India’s petrochemical sector isn’t just about fuels — it’s the backbone of modern manufacturing and development.

📊 Key Stats

| Parameter | Value |

|---|---|

| Global Rank in Chemicals | 6th |

| Industry Value (2022) | $178 billion |

| Projected Value (by 2025) | $300 billion |

| GDP Contribution | ~10% (expected 12% by 2025) |

| Direct Employment | 2 million+ |

| Export (2022–23) | $31.8 billion |

🏭 Major Product Segments

- Polymers: Polyethylene (PE), Polypropylene (PP), PVC

- Fertilisers

- Paints and Coatings

- Petro-based consumer goods: packaging, textiles, household items, plastic pipes and cables.

✅ These feed into infrastructure, agriculture, healthcare, automobile, and FMCG sectors — making petrochemicals a strategic industry.

Top Global Players

Let’s now look at who leads in production, consumption, export and import of petroleum products:

| Category | Top Countries |

|---|---|

| Producers | USA, Russia, Saudi Arabia, Canada, China |

| Consumers | USA, China, India, Japan, Russia |

| Exporters | USA, Russia, Saudi Arabia, Iraq, Canada |

| Importers | China, India, Japan, South Korea, Germany |

🧠 Inference:

- The US is dominant across the board.

- India is among top consumers and importers, reflecting its energy dependency.

Challenges Faced by India’s Petrochemical Industry

Despite its success, several bottlenecks remain:

1. Heavy Import Dependency

- India imports most of its crude oil — exposing it to price shocks, geopolitical tensions, and currency risks.

2. Lack of Feedstock Diversification

- Limited use of alternative feedstocks (like coal-to-olefins or biomass) reduces competitiveness.

3. Logistics & Storage Constraints

- Inefficiencies in supply chains, inadequate storage infrastructure, and transport delays increase costs and affect productivity.

📌 Final Summary

| Dimension | Insight |

|---|---|

| Location Factors | Based on raw material, market, port access, infrastructure, policies, and environment |

| India’s Position | Emerging hub with global collaborations, strong industrial growth, and increasing exports |

| Global Role | India is a major consumer and importer but moving toward becoming a significant exporter |

| Challenges | Import dependence, logistics issues, and lack of feedstock innovation |