Nickel

Let us begin with the very basic question:

What is Nickel?

Nickel is a silvery-white metal. But remember – like gold or silver, it is not found in its native or free state in nature. It always occurs in combination with other metals – most notably copper, uranium, and others. That means, to extract nickel, we don’t just dig out “pure” nickel – we get it as a part of a larger mineral matrix.

Now, what makes nickel such a valuable industrial metal? Let’s understand its physical and chemical properties:

- Low electrical conductivity – Not a great conductor like copper.

- High resistance to corrosion – Doesn’t rust easily.

- Strong at high temperatures – It retains its strength even in extreme heat.

- Can become magnetised – Meaning it has ferromagnetic properties.

These traits make nickel suitable for a wide range of industrial applications.

Geological Formation of Nickel

Now, from where does this metal originate in the Earth’s crust? There are two major geological processes through which nickel is formed:

1. Magmatic Sulphide Deposits:

- Think of magma beneath the Earth’s surface – hot, molten rock.

- As it cools and solidifies slowly, certain sulphide minerals crystallise, trapping nickel along with copper.

- These are called Nickel-rich sulphide minerals, and such deposits are typically found in igneous rocks.

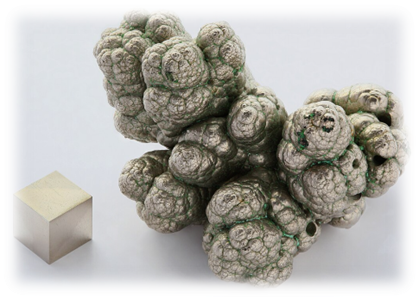

2. Laterite Deposits:

- In tropical climates, where rainfall and heat are intense, ultramafic rocks (rich in magnesium and iron) undergo chemical weathering over millions of years.

- This process concentrates nickel in the form of oxides and silicates in the soil profile.

- These are called lateritic nickel deposits, and they are the dominant form in countries like India.

Applications of Nickel

Nickel is a highly versatile metal, and its uses span across multiple industries. Let’s categorize them logically:

1. Alloy Formation (Primary Use)

Nickel is mostly used to make alloys, which are mixtures of metals to enhance strength, resistance, and durability:

- Stainless Steel → Combination of iron + nickel. Used in utensils, medical instruments, construction.

- Nichrome → Nickel + Chromium. Used in heating elements like toasters, electric ovens, etc., due to its resistance to oxidation and heat.

- Copper-Nickel Alloy → Used in desalination plants – where seawater is converted into freshwater.

- Nickel-Aluminium Alloys → Key material in aerospace and internal combustion engines, due to lightness and heat resistance.

2. Miscellaneous Uses

- Batteries – Nickel is used in rechargeable batteries, especially Nickel-Cadmium and Nickel-Metal Hydride types.

- Catalysis – In industries producing soap or processed foods, nickel acts as a catalyst in hydrogenation (hardening oils).

- Defence and Currency – Used in armour plating, bullet jackets, and even in coins (such as rupee coins).

- Glass Manufacturing – Adding nickel imparts a green tint to glass.

Major Nickel Alloys – Easy to Remember!

| Alloy | Components | Application |

| Stainless Steel | Iron + Nickel | Kitchenware, construction |

| Rupee Coins | Nickel + Copper/Silver | Currency |

| Nichrome | Nickel + Chromium | Electrical appliances |

Distribution of Nickel: India and the World

In India

Nickel in India occurs in three main mineral forms:

- Oxides

- Sulphides

- Silicates

Key Locations:

- Sukinda Valley, Jajpur district (Odisha) – Largest deposit; lateritic nickel in oxide form.

- East Singhbhum, Jharkhand – Found as sulphide, associated with copper.

- Jaduguda, Jharkhand – Nickel appears alongside uranium.

- Other occurrences: Karnataka, Kerala, Rajasthan.

Another interesting source is:

- Polymetallic Sea Nodules – Found on the ocean floor, rich in nickel, manganese, copper, and cobalt. India has rights to explore such deposits in the Central Indian Ocean Basin under the UN.

Important Fact:

India does not produce nickel metal domestically. We are entirely dependent on imports.

- Major sources: USA, Saudi Arabia, Canada, UAE.

Nickel Reserves and Production: A Global Perspective

Let’s look at a comparative table for better clarity:

India’s Nickel Ore Reserves (2020)

| State | Reserves (in MT) | Share |

| Odisha | 175 | 93% |

| Jharkhand | 9 | 4.7% |

| Nagaland | 5 | 2.6% |

| Total | 189 MT | 100% |

World’s Nickel Metal Reserves in Million tons (2024)

| Country | Reserves |

| Indonesia | 55 |

| Australia | 24 |

| Brazil | 16 |

| World Total | >130 |

World’s Nickel Production in thousand tons in 2024

| Country | Production |

| Indonesia | 2200 |

| Philippines | 330 |

| Russia | 210 |

Conclusion: Why is Nickel Important for India?

Nickel is critical for:

- Industrial manufacturing

- Strategic sectors like defence and aerospace

- Modern technology like batteries and electronics

Yet, India’s complete import dependence, despite having reserves, poses a strategic and economic challenge. There’s an urgent need to:

- Develop domestic extraction technologies

- Explore sea-bed mining for polymetallic nodules

- Reduce reliance on foreign sources